Cooltherm are Turbomiser™

Cooltherm - Geoclima's ultra-efficient Turbomiser™ chiller is the most efficient chiller of its type on the market today: thanks to the use of Turboco compressors, it is able to reduce energy costs by up to 50% compared with traditional units that use screw or reciprocating compressors. Turbomiser chiller has won several awards, including CIBSE, the most prestigious award for technology with low environmental impact.

In addition to ultra-efficient performance, Turbomiser improves comfort and productivity levels in buildings thanks to its innovative design and continuous monitoring. And, with its frictionless magnetic bearings, service and maintenance costs are significantly reduced. The Turbomiser chiller is based on a combination of technologies designed to reduce energy consumption, minimise or avoid leaks, reduce refrigerant charge and ensure reliable operation and deliver quiet running.

Cooltherm don't just sell Turbomiser™, we are Turbomiser™!

"It's simple, nobody knows Turbomiser™ like Cooltherm Do"

Using magnetic levitation Turbocor compressors gives the following benefits:

- Reduces energy consumption

- Avoids refrigerant leakage

- Reduces maintenance

- Compact and lightweight

- Exceptional noise reduction

- Low start-up current

Reduce Energy Consumption with Turbomiser and Turbocor

The latest version of the technology, the Turbomiser™ II, requires between 30-50% less energy compared with conventional systems based on screw, scroll or reciprocating technology. This dramatic reduction in power requirement is achieved without compromising the cooling performance of the machine.

Avoid Refrigerant Leakage

Refrigerant leaks are unnecessary, costly and – entirely avoidable. They are a consequence of poor design and/or maintenance of plant. The Turbomiser™ is designed to minimise or avoid leaks altogether, through reducing the number of components and joints in the system.

Reduced Maintenance

As a result of the oil-free design and limited number of moving parts, the Turbomiser™ requires no oil changes and much reduced servicing to ensure efficiency and reliable running. The technology is highly reliable and proven to save the end user cost and reduce down time.

Packs lots of cooling power into a small space

Turbomiser™ is compact and lightweight due to the exceptional Turbocor compressor. The compressor weighs just 125kg compared with 600kg for typical screw and reciprocating machines. This frees up plant rooms, reduces loading on rooftops and enables chillers to be sited in spaces considered too tight for standard chiller technology.

Exceptional noise reduction

Noise is a growing issue, particularly with the introduction of air conditioning to buildings in built-up and residential areas. The Turbomiser™ addresses this through exceptionally quiet operation, down to 67dbA at five metres. Due to its design, the Turbomiser™ Chiller is also virtually vibration free – there is no need for anti-vibration mountings or special supports.

Low start-up current

Conventional chillers may require up to 600 Amps starting current, putting a huge draw on a building’s electricity supply – and sometimes requiring an expensive upgrade of the sub-station. Because the Turbomiser™ chiller is based on inverter-controlled Turbocor compressors, it requires just 2 Amps to start, saving cost and maintaining headroom for other essential services.

Turbomiser Products

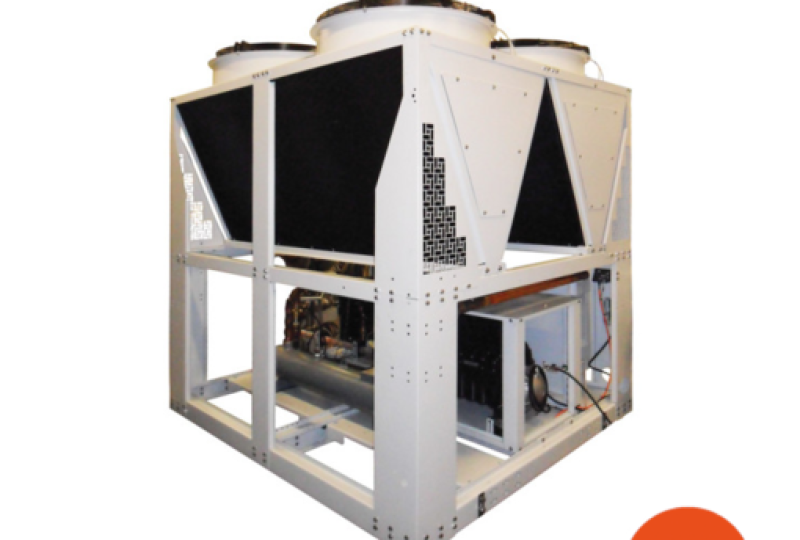

TMA Air Cooled Chiller

Air cooled chiller with Turbocor centrifugal compressors and axial fans for outdoor installation

TMA ES Adaibatic Chiller

Air cooled chiller with Turbocor centrifugal compressors, axial fans and Evaporative System for outdoor installation

TMA Free Cooling Chiller

Air cooled chiller with Turbocor centrifugal compressors, axial fans and Free Cooling system for outdoor installation

TMH Water-Cooled Chiller

Water cooled chiller with Turbocor centrifugal compressors for indoor installation

TSE Remote Condenser Chiller

Condenserless water chiller with Turbocor centrifugal compressors to be connected with a remote condenser (RCE) for indoor installation

TSA Turbocor Condenser Chiller

Condensing unit with Turbocor centrifugal compressors, air condensation and axial fans for outdoor installation

Standard Chiller Technical Data

-

Turbomiser (TMA Air-Cooled Turbocor) Data Sheet ∙ 2mb

-

Turbomiser (TMA Adaibatic Turbocor) Data Sheet ∙ 2mb

-

Turbomiser (TMA Free-Cooling Turbocor) Data Sheet ∙ 2mb

-

Turbomiser (TMH Water-Cooled Turbocor) Data Sheet ∙ 2mb

-

Turbomiser (TSE Remote Condenser Turbocor) Data Sheet ∙ 2mb

-

Turbomiser (TSA Turbocor Condensing Unit) Data Sheet ∙ 2mb